Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

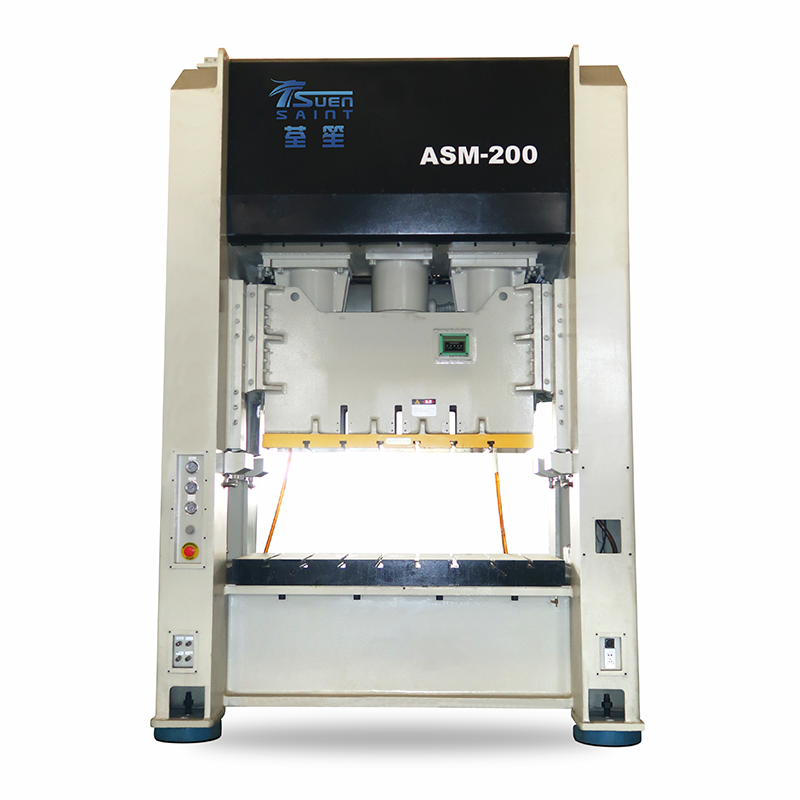

TSUENSAINT ASA/M Series Servo Press Continuous Metal Punching Machine 25-315T

The TSUENSAINT ASA/M series servo press continuous automatic hole punching press equipment, ranging from 25 to 315 tons. Engineered for advanced metal perforating, it features low noise and vibration, enhancing machine stability and ensuring precise product accuracy. The servo-driven system not only extends die life but also delivers consistent and high-quality perforations, ideal for applications demanding stringent standards.

- Product Details

-

Download

Metal Punching Machine

Product Description

The TSUENSAINT ASA/M series servo press continuous automatic hole punching press equipment represents a cutting-edge solution for metal perforation across diverse industries. Its servo-driven mechanism not only guarantees low noise and vibration but also facilitates enhanced control, contributing to superior accuracy in hole punching operations. The equipment's adaptability across a tonnage range of 25 to 315 tons makes it suitable for a wide spectrum of applications, from intricate patterns to heavy-duty perforations.

Product Features

- Servo Press Technology: Precision hole punching is achieved through advanced servo-driven technology, ensuring consistent and accurate results.

- Low Noise and Vibration: Engineered for a quieter operation, minimizing noise and vibration for a more comfortable work environment.

- Enhanced Stability: Improved machine stability reduces errors, contributing to reliable and uninterrupted perforating processes.

- Adaptive for Varied Applications: Versatility across a range of applications, from intricate patterns to heavy-duty perforations, offers flexibility for diverse production needs.

Product Advantages

- Efficient Control Systems: The metal punching machine is outfitted with sophisticated control systems that simplify programming and monitoring tasks for operators. This feature streamlines the setup process, allowing for easy adjustment of parameters, contributing to the achievement of optimal production conditions and minimizing the learning curve for operators.

- High-Speed Operation: With a capability for high-speed performance, the metal punching machine excels in mass production scenarios. Its ability to operate at elevated speeds not only enhances overall productivity but also reduces cycle times, making it well-suited for applications where efficiency and throughput are paramount.

- Consistent Accuracy: The servo-driven technology of the machine ensures not only speed but also consistent accuracy in hole punching operations. This precision is vital for meeting stringent quality standards and accommodating the production of components with tight tolerances, contributing to the overall reliability of the perforating process.

- Operational Flexibility: Designed for adaptability, the machine is versatile across different metal materials and thicknesses. This operational flexibility allows manufacturers to use the equipment for a wide range of industrial applications, making it a valuable asset in diverse manufacturing environments where varying materials are employed.

Product Specification

| Specification | ASA-25 | ASA-35 | ASA-45 | ASA-60 | |||||

| Nominal | Tons | 25 | 35 | 45 | 60 | ||||

| Rated tonnage point | mm | 3.2 | 3.2 | 3.2 | 4 | ||||

| Stroke lenght | mm | 70 | 70 | 80 | 120 | ||||

| Stroke | SPM | ~120 | ~110 | ~100 | ~90 | ||||

| Die height(S.D.A.U) | Mm | 195 | 220 | 250 | 310 | ||||

| Slide adjustment | mm | 50 | 55 | 60 | 75 | ||||

| Slide area | mm | 300×230 | 360×250 | 400×300 | 500×360 | ||||

| Bolster area | mm | 680x300x70 | 800x400x70 | 850x440x80 | 900x500x80 | ||||

| Shank hole | mm | φ38.1 | φ38.1 | φ38.1 | φ50 | ||||

| Maximum counterbalancer capacity | Manual | ||||||||

| Presses precision | GB/T 23280(JIS1级) | ||||||||

| Nominal | Tons | ASA-80 | ASA-110 | ASA-160 | |||

| Rated tonnage point | mm | 80 | 110 | 160 | |||

| Stroke lenght | mm | 5 | 6 | 6 | |||

| Stroke | SPM | 150 | 180 | 200 | |||

| Die height(S.D.A.U) | Mm | ~70 | ~60 | ||||

| Slide adjustment | mm | 340 | 360 | 460 | |||

| Slide area | mm | 80 | 80 | 100 | |||

| Bolster area | mm | 560×420 | 650×470 | 700×550 | |||

| Shank hole | mm | 1000x550×90 | 1150x600x110 | 1250x800x140 | |||

| Maximum counterbalancer capacity | φ70 | φ80 | φ80 | ||||

| Presses precision | Electric | ||||||

| Nominal | Tons | ASA-200 | ASA-260 | ASA-315 | |||

| Rated tonnage point | mm | 200 | 260 | 315 | |||

| Stroke lenght | mm | 6 | 6 | 6 | |||

| Stroke | SPM | 200 | 250 | 250 | |||

| Die height(S.D.A.U) | Mm | ~50 | ~45 | ~40 | |||

| Slide adjustment | mm | 460 | 500 | 550 | |||

| Slide area | mm | 110 | 120 | 120 | |||

| Bolster area | mm | 850×630 | 950×700 | 950×700 | |||

| Shank hole | mm | 1400x820x160 | 1500×840×180 | 1600x900x180 | |||

| Maximum counterbalancer capacity | φ100 | φ100 | φ100 | ||||

| Presses precision | Electric | ||||||

Download

-

ASA.pdf

Download ASA.pdf